Sekha Nama Bowl

Selelekela

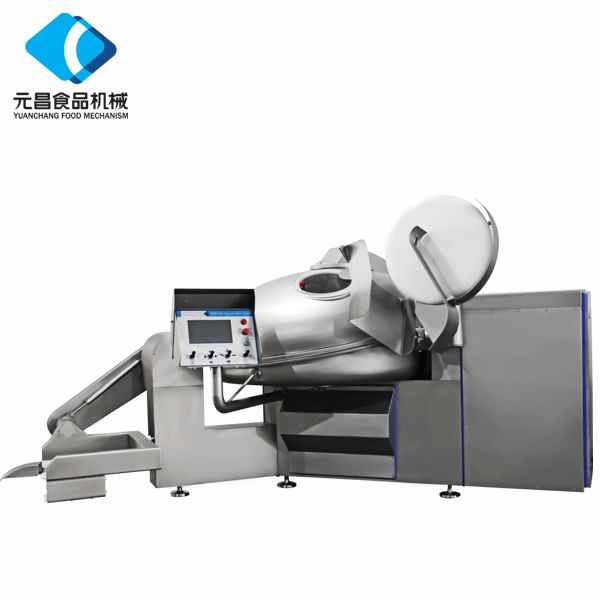

YC Mechanism Vacuum Bowl Cutter Technology e thehiloe ho nts'etsopele e sebetsang e nang le boiphihlelo ba lilemo tse ngata.Mochini oa morao-rao, o nang le bokhoni bo phahameng bakeng sa tlhahiso ea indasteri ea mefuta eohle ea li-sausage tsa boleng bo holimo, tse kang li-sausage tse omeletseng, li-sausage tse phehiloeng, li-sausage tse phehiloeng le thepa e entsoeng ka makotikoting.Re tsebahala indastering eohle ea nama ka boleng le ts'epahalo ea mefuta ea rona ea li-cuttings tsa likotlolo, ho etsa Mehlala e seng mekae ho tloha ho 125 L ho isa ho 420 L.

Vacuum Cutter Series e kopantsoe le Siemens Motor, Jeremane Busch vacuum pump, USA EMERSON kapa Denmark DANFOSS thekenoloji ea taolo ea maqhubu, Sweden SKF bearings, Swiss ABB electrics, Japan Mitsubishi PLC le likhetho tsa likarolo tse ling tse tsoang kantle ho naha ha li kopuoa.

Ka lebaka la tšebelisano e babatsehang ea ho itšeha ka lebelo, lebelo la sekotlolo le mofuta oa lithipa, re fana ka theknoloji ea ho sebetsana le likotoana tse kholo tsa nama.Ho boloka nako ha se eona feela molemo oa ho sebelisa mochini o sehang lijana ho etsa emulsify, chop e mahoashe kapa lihlahisoa tsa chop tse ntle.Hase feela hore mokhoa oa ho sila / motsoako / regrind o ja nako, empa o lahleheloa ke monyetla oa ho ntša palo e kholo ea protheine ho tloha motsoako oa nama ea hau e le hore u ka hlahisa lihlahisoa tsa boleng bo phahameng, tse nang le boleng.Bongata ba ho ntša liprotheine bo fetolela ho eketseha ho tlamang le ho boloka boima ba 'mele, ho lekanang le ho pheha ho fokolang le ho eketseha ha chai.

Mohlala

| Mohlala | Bolumo (L) | Ho poma Lebelo (r/mots) | Lebelo la Pitsa (r/mots) | Lebelo la ho lahla (r/mots) | Matla (KW) | Cutter Quantity (Khomphutha) | Rated Voltage (V) | Boemo ba Vacuum (Mpa) | Boima ba 'mele (Kg) | Litekanyo (mm) |

| ZKZB-125 | 125 | 300-4200 | 0-10 | Koloi e sa fetoheng e sa fetoheng (Speed gear-shift e boetse e fumaneha ha o e kopa) | 35.2 | 6 | 380 | -0.085 | 2425 | 2160*1750*1300 |

| ZKZB-200 | 200 | 400-4000 | 0-10 | 86.4 | 6 | 380 | -0.085 | 4100 | 3280*2590*1500 | |

| ZKZB-330 | 330 | 360-3600 | 0-6 | 102.4 | 6 | 380 | -0.085 | 5000 | 3850*3000*1750 | |

| ZKZB-420 | 420 | 360-3600 | 0-6 | 144.4 | 6 | 380 | -0.085 | 5800 | 3940*3030*18 |

Kopo

Melemo ea Bowl Meat Cutter:

● Kaho ea tšepe e sa hloekang ea boemo bo holimo ea SUS 304 e nang le Sehahi sa lihlooho tse 6 tsa thipa.

● Libaka tse boreleli tse fanang ka moralo oa bohloeki ka ho fetisisa oa Cutter bakeng sa ho hloekisa habonolo le ka potlako.

● Moralo o mocha oa li-axle shaft.

● Mokhoa o ikemetseng oa ho fepa metsi (ho ikhethela).

● Sekotlolo sa tšepe sa boleng bo phahameng se tiileng se kentsoeng ka li-bearings tse kholo tse bophara bo boholo 'me se fana ka tiiso ea ho itšeha ntle le Vibration.

● Touch-Screen Monitor System (Metsamao eohle - Ho Laola/Ho laolla, Sekoaelo sa Bowl, Lithipa & Lebelo la Bowl, Vacuum system, Batch No, Nako ea ts'ebetso, Thempereichara ea lihlahisoa, Bophahamo ba metsi, tlhahlobo ea phoso) ka ho thetsa monoana ho Coloured. Pontšo ea LCD.

● E entsoe ka lifensetere tsa ho shebella le lesoba la ho tlatsa thepa.

● Smooth control sehiloeng-ho kopanya lipotoloho le ho potoloha ha sekotlolo ho fana ka mefuta e mengata ea mananeo a ka sebelisoang ts'ebetsong e 'ngoe le e' ngoe ea ho itšeha.

● Boemo ba ho sisinyeha bo tlase ka lebaka la hlooho ea thipa e leka-lekaneng le sistimi e fokolang ea lerata.

● Vacuum Bowl Cutter e boholo ho tloha: 125, 200, 330, 420, 500 Lithara ea matla.

Advanced-Design e netefatsa ts'ebetso e nepahetseng ho mechini e hlileng e lulang e sebetsa.Ha ho mongobo kapa likaroloana tse ka fihlang ho li-bearings tsa thipa, ka lebaka la sistimi e tiisitsoeng ea thipa e nang le tokelo ea molao le li-bearings tsa lubricating li ka etsoa ntle le ho senya likarolo tse arohaneng le ts'ebetso e se nang mathata.